Product details

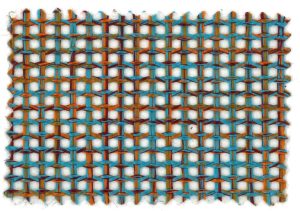

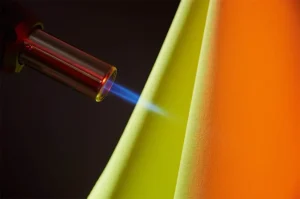

The ring twisting process, Also known as double twist process, emerges as an essential method to enhance tensile and friction resistance in textile yarns, with a particular focus on applications such as warping. This advanced technique allows us to face specific challenges in various sectors. The breadth of our raw material options underscores the versatility of the process, spanning polyester (PES), polyamide (PA), polybutylene terephthalate (PBT), polypropylene (PP) and custom blends of these materials. Besides, We offer a range of titles ranging from 75 until 3000 deniers, ensuring a variety of options for different applications. The twists, that vary from 40 a 600 turns per meter, give specific characteristics to the ring twisted thread, highlighting its ability to resist intense tensions and frictions. This process is essential in demanding sectors such as fashion., decoration, industrial tape, automotive and filtration, where strength and durability are critical to the performance of the final product.

Main Categories

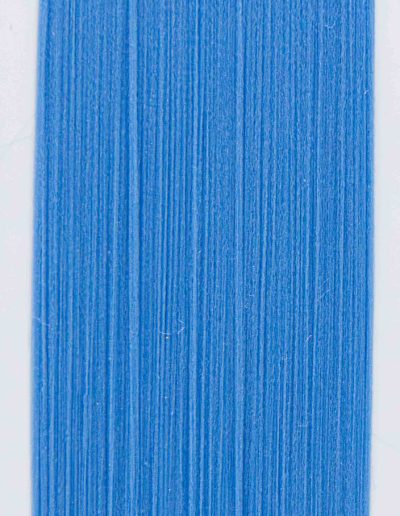

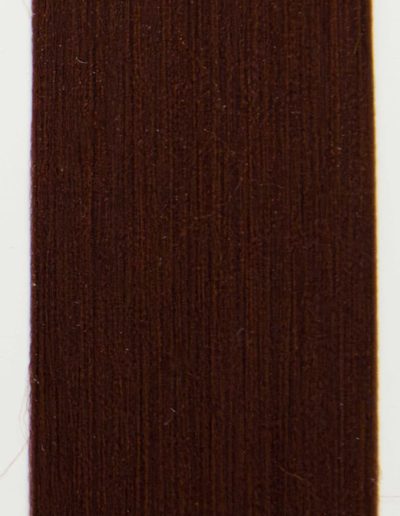

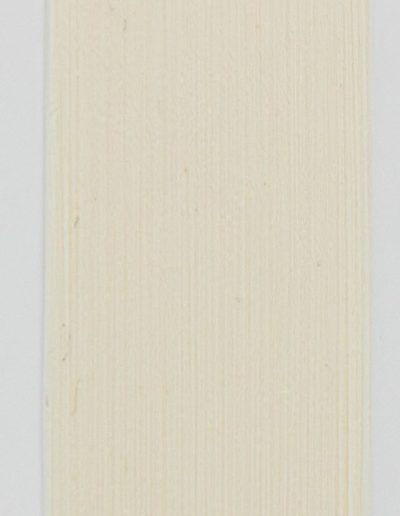

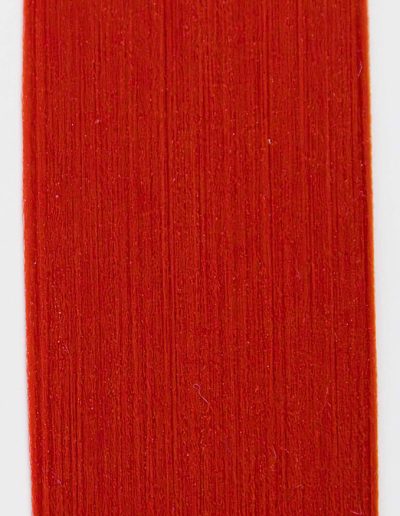

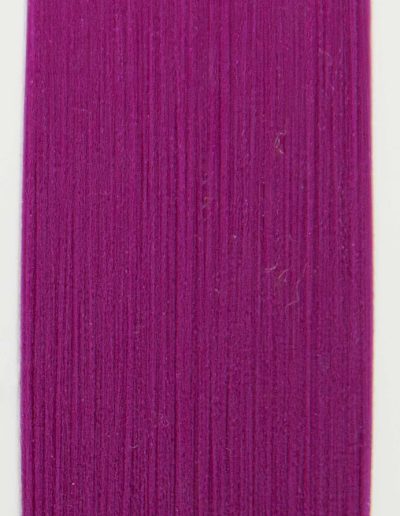

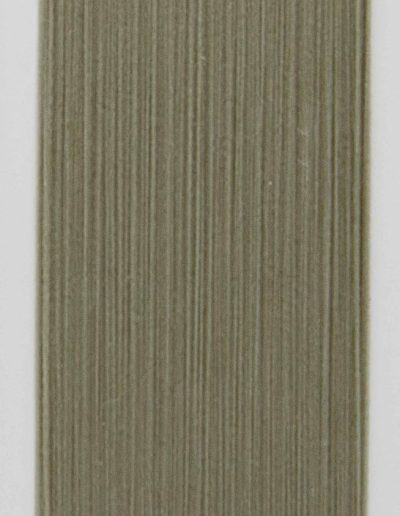

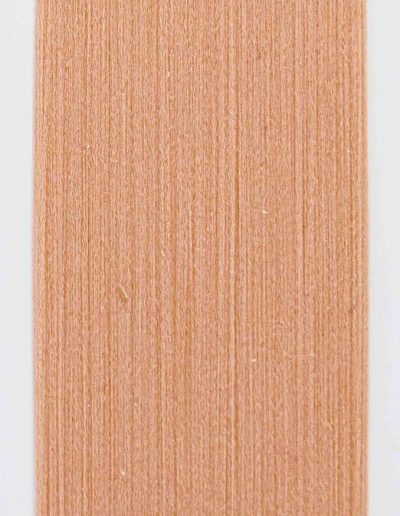

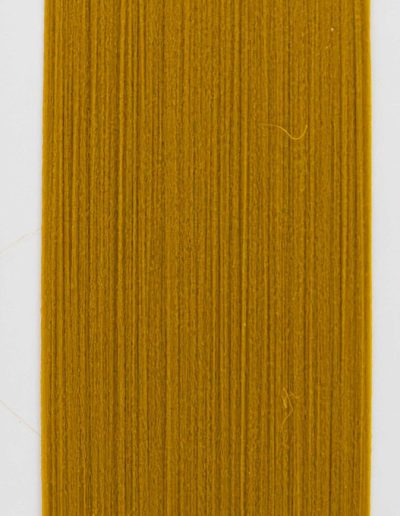

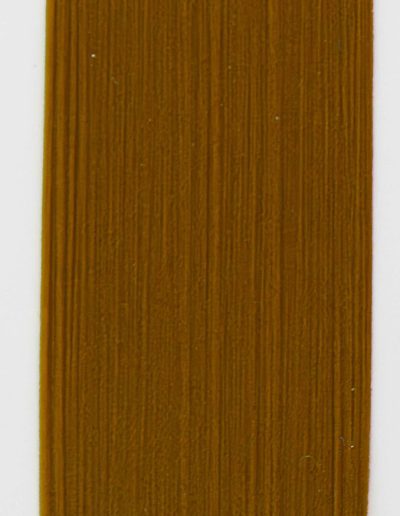

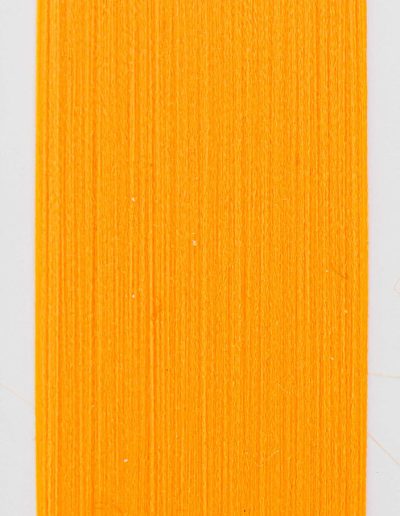

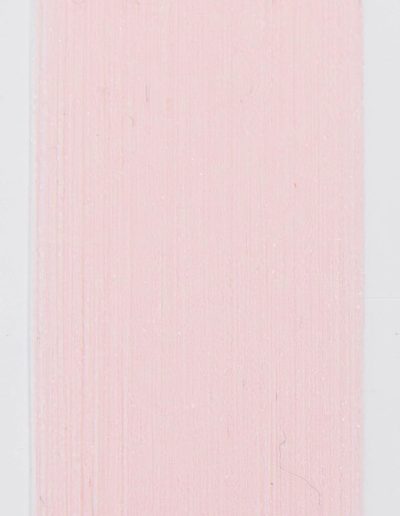

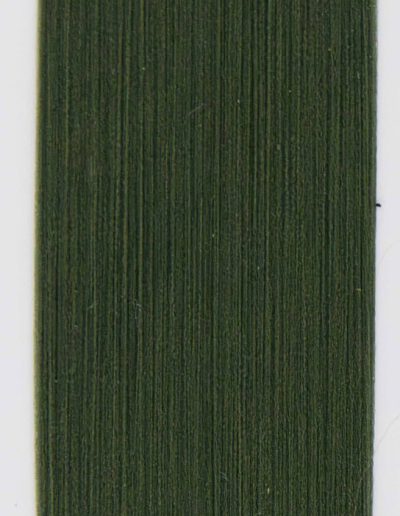

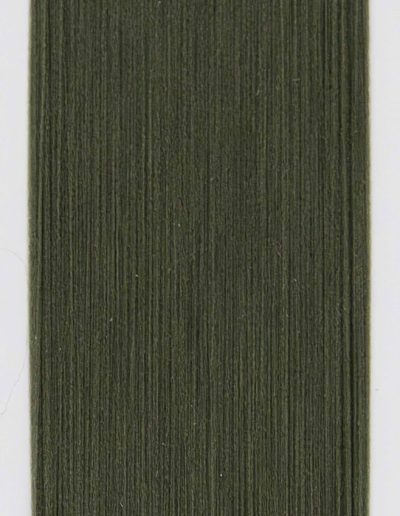

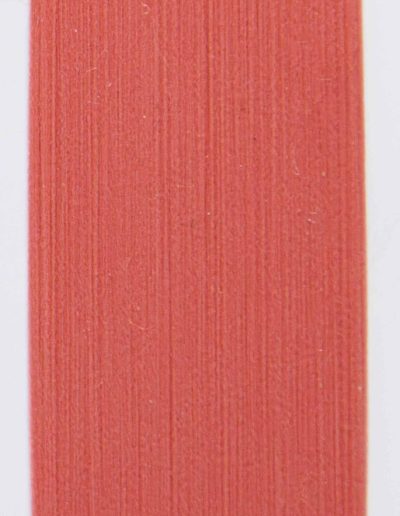

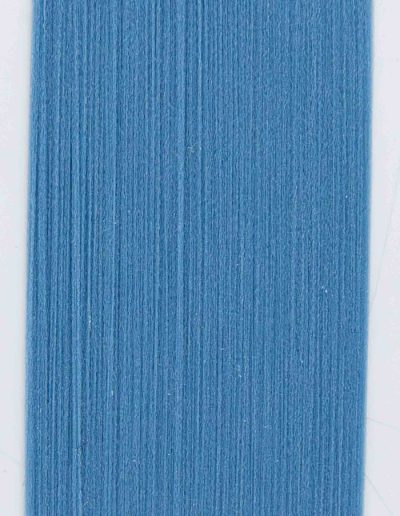

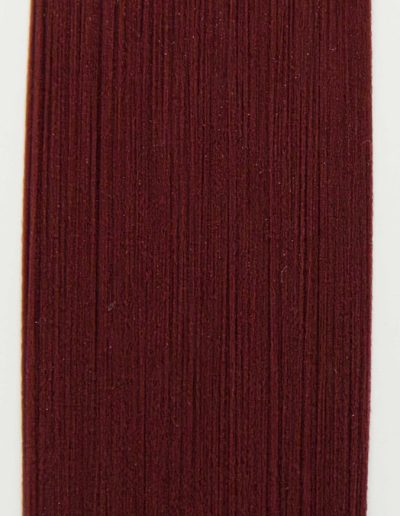

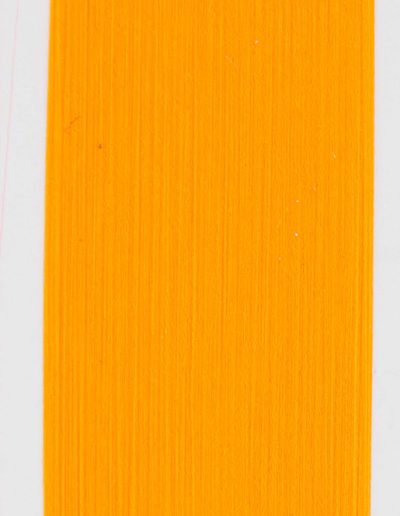

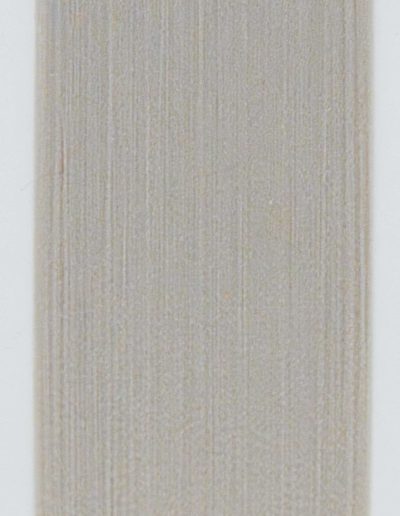

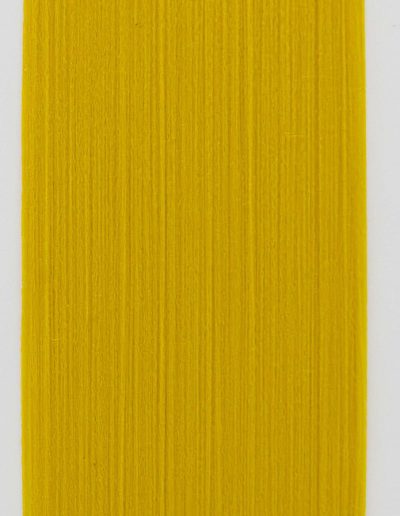

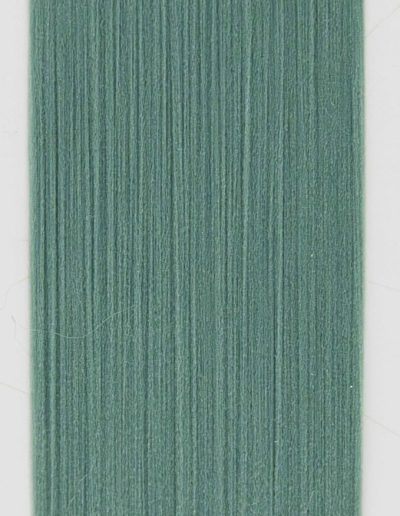

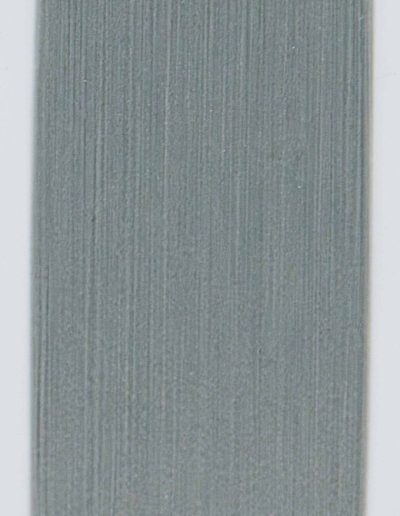

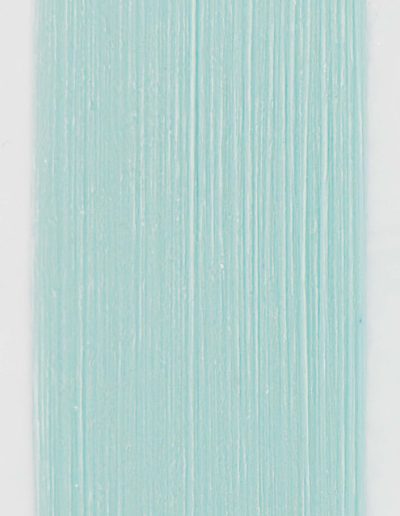

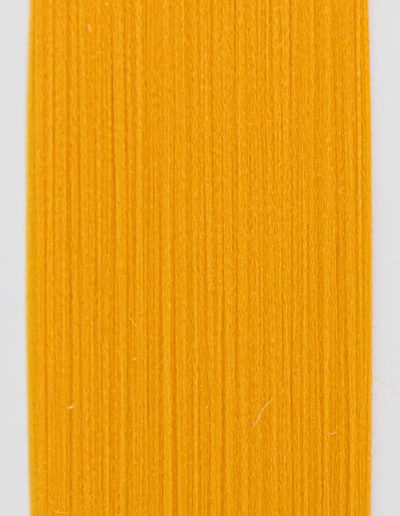

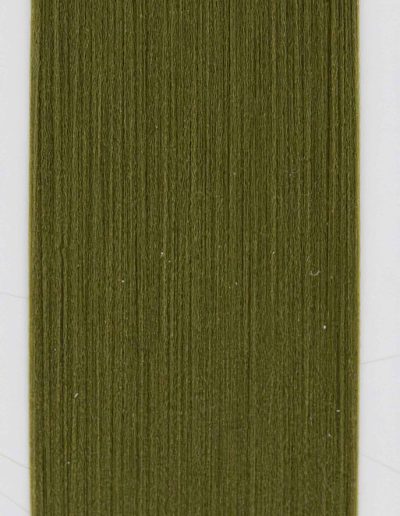

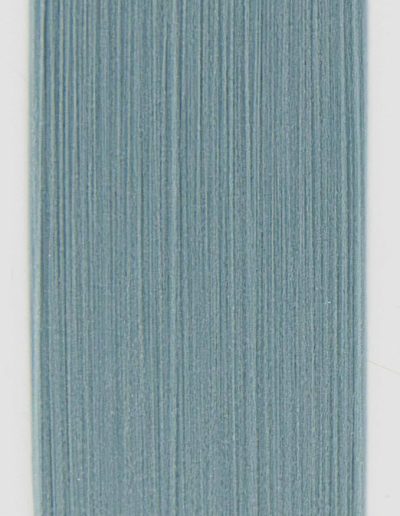

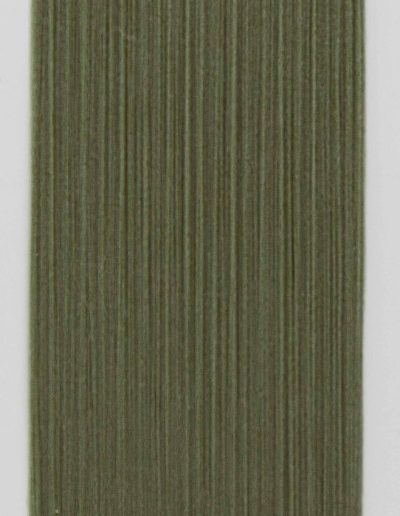

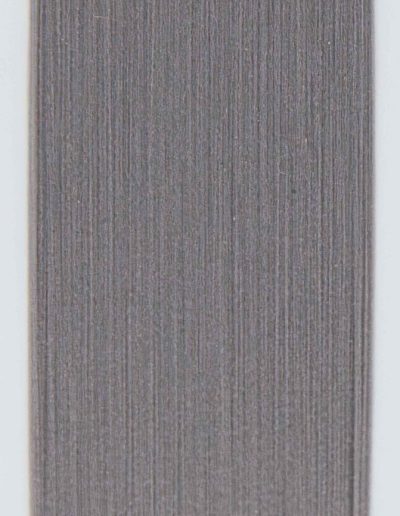

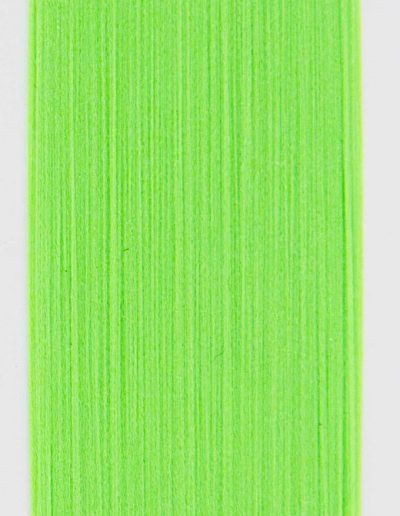

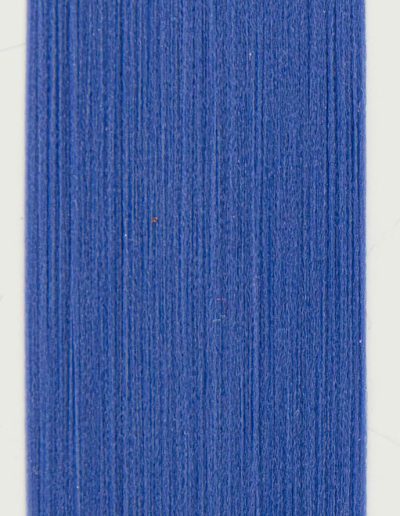

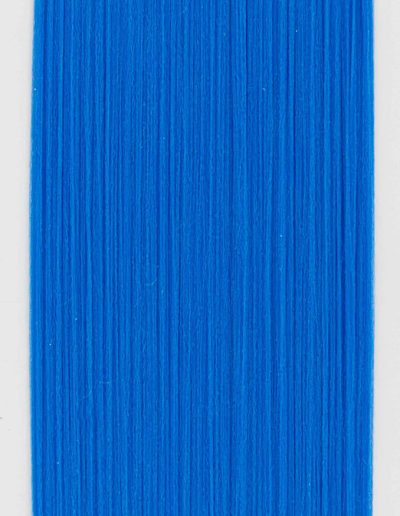

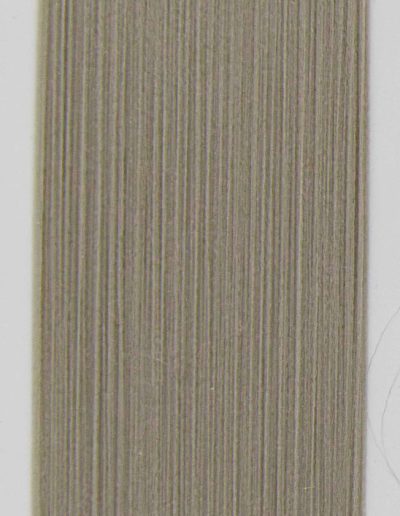

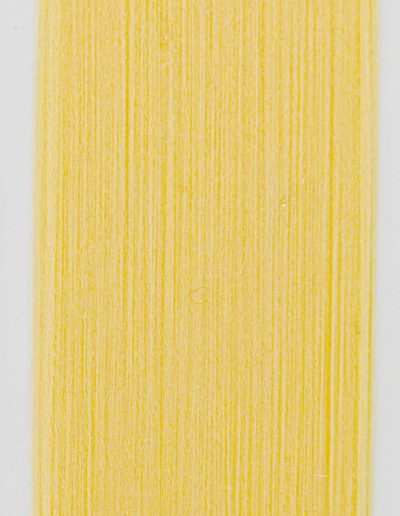

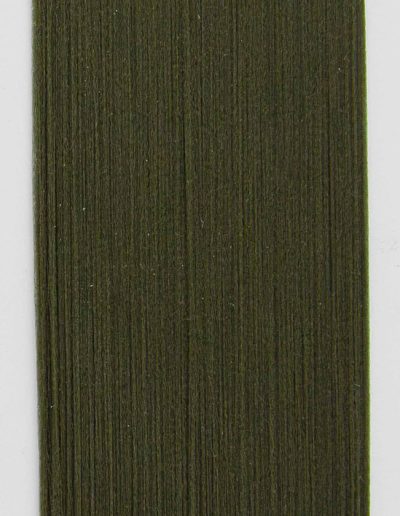

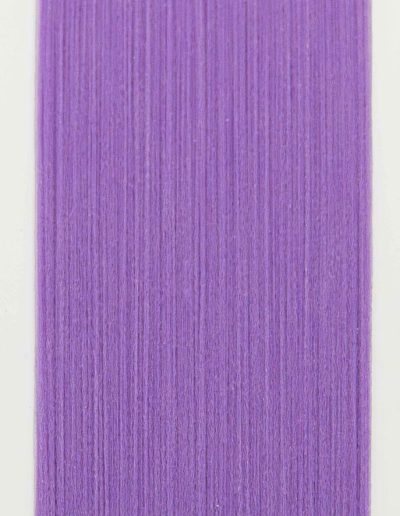

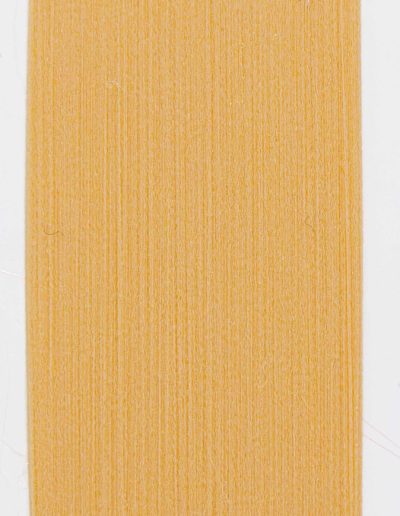

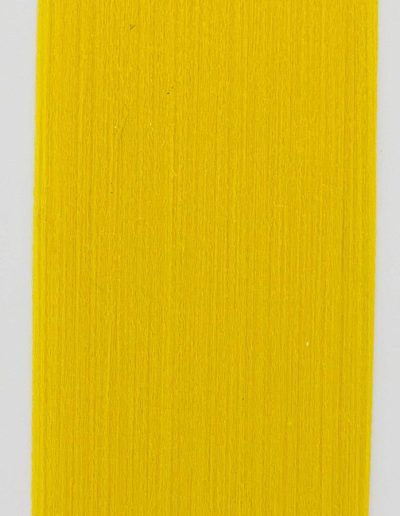

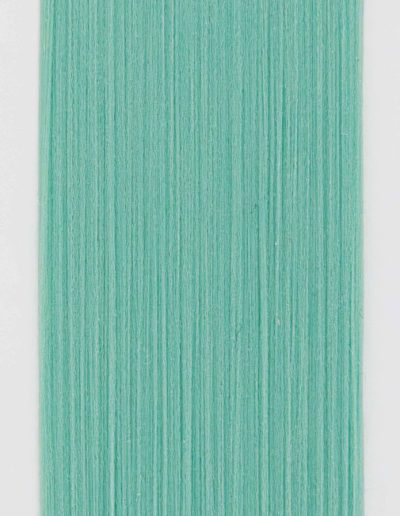

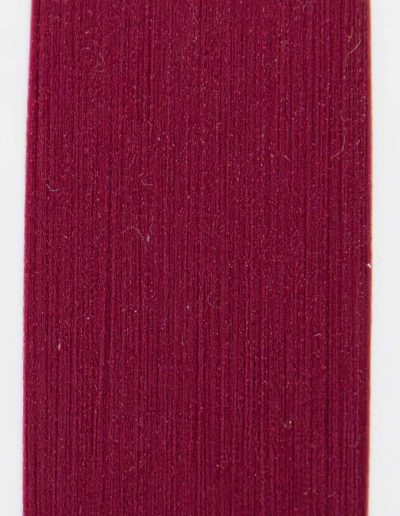

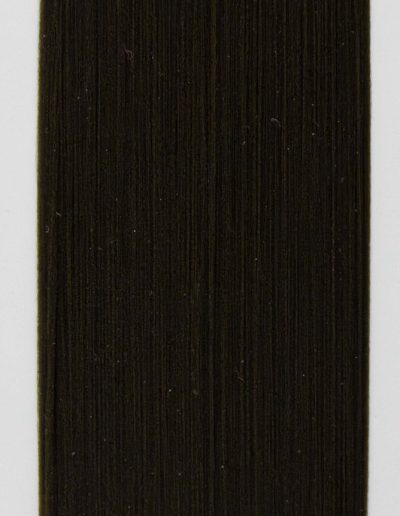

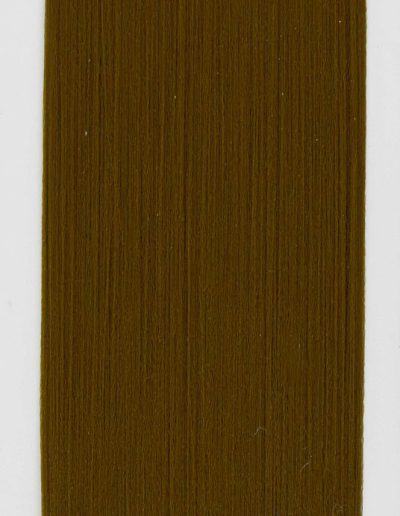

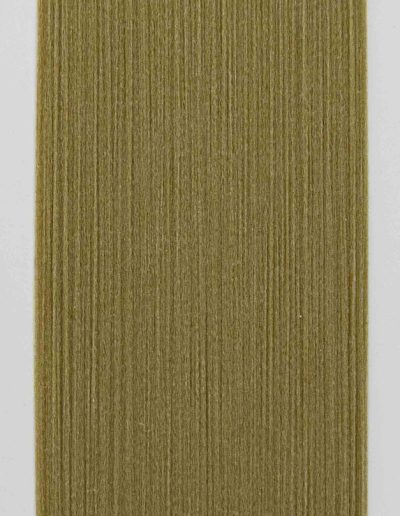

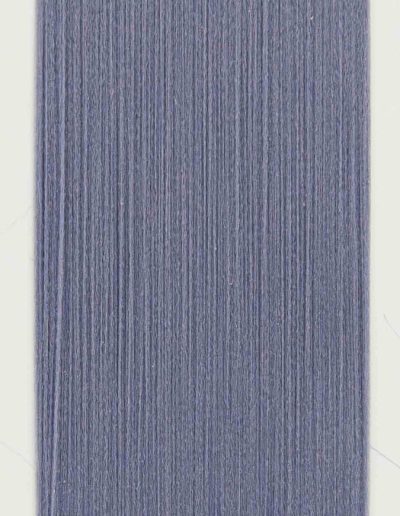

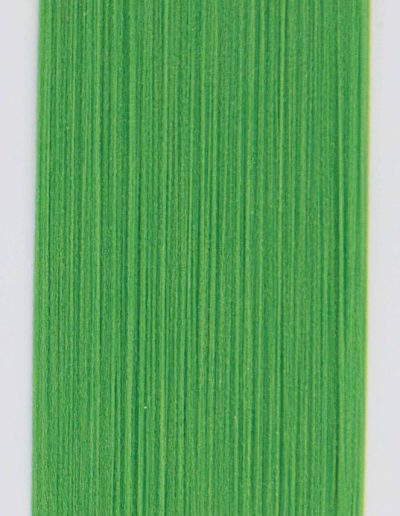

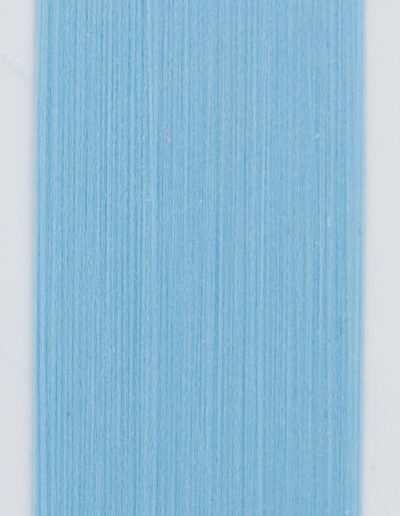

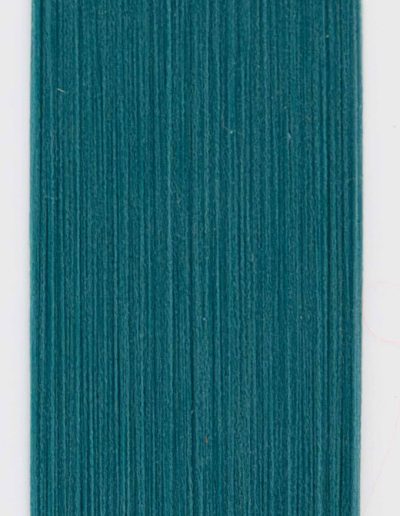

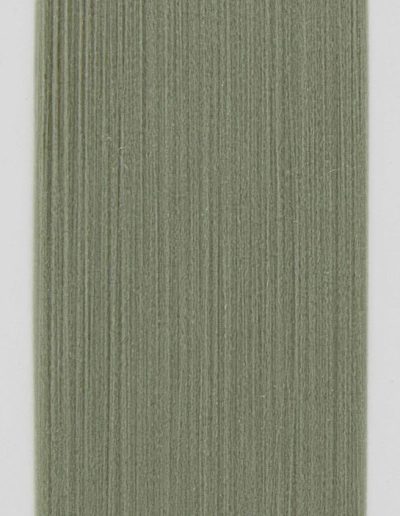

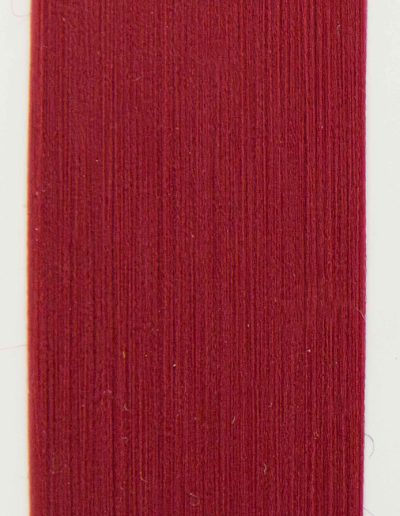

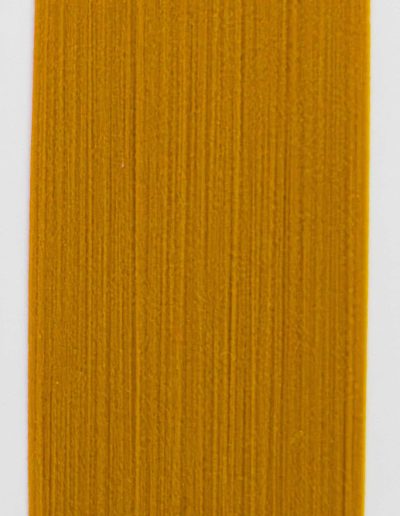

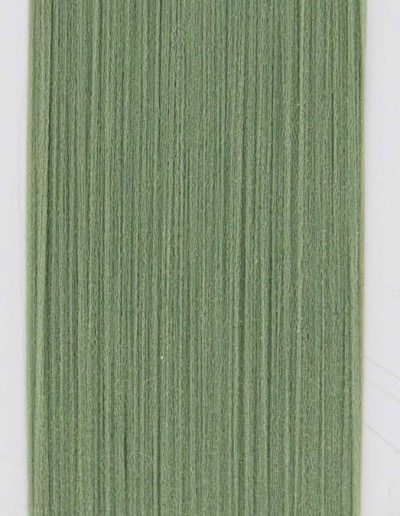

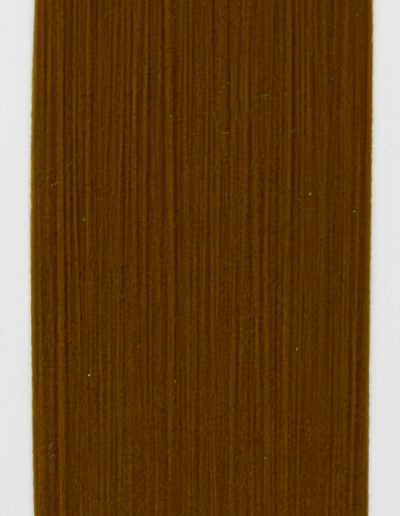

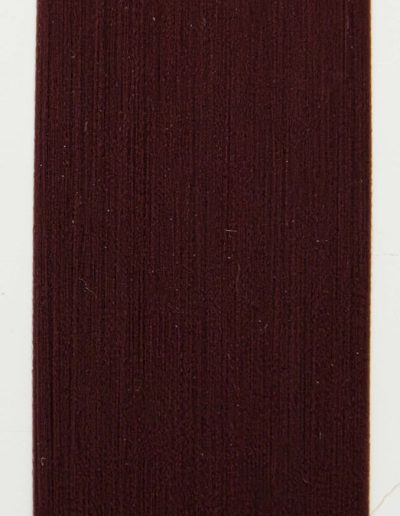

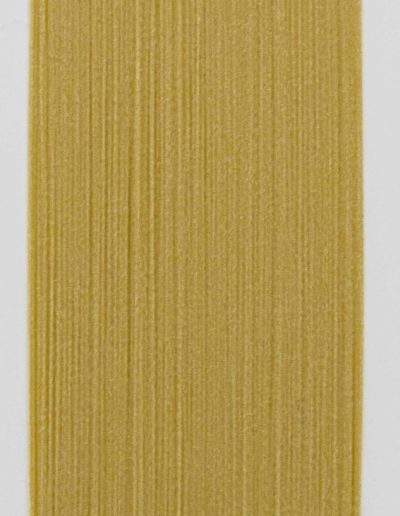

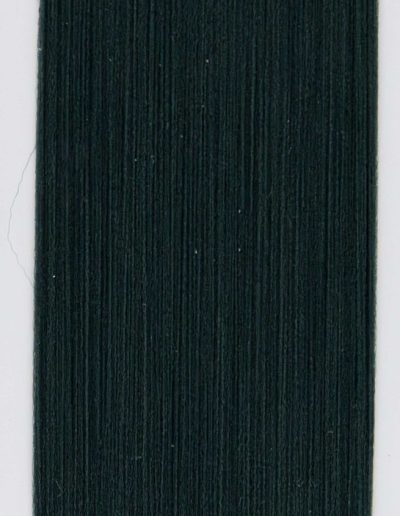

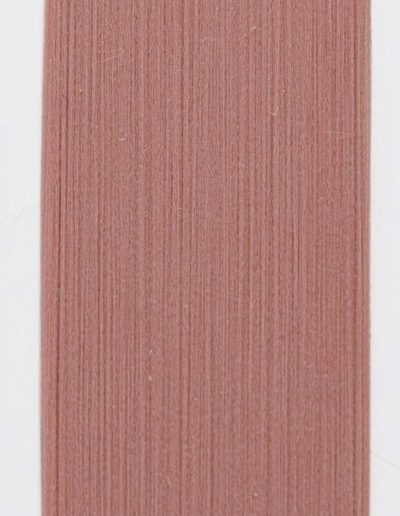

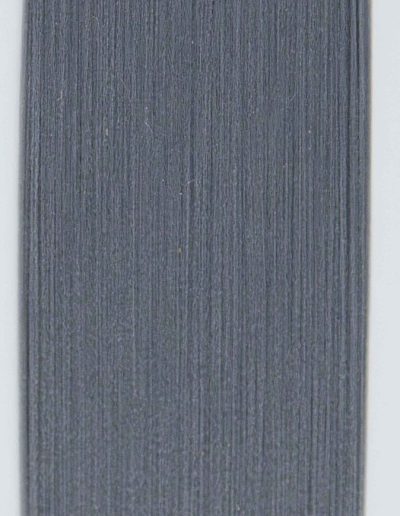

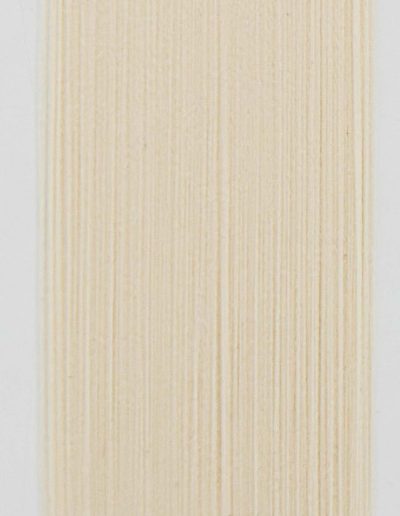

color gallery